Eco Control 2

Eco Drain 12

Alarm Test

To test pre-alarm function press the Test button for more than 1 minute but less than 5 minutes. To test alarm function press the Test button for more than 5 minutes.Eco Drain 31-32

Maintenance Reset

Remove control unit from top of drain. Press and hold test button for at least 5 seconds. Reinstall control unit on top of drain.

Test Alarm Function

Press and hold the Test button for at least one minute.Sigma

Level 0

00000

Level 1

BEDX1

Level 2

BEDX2

Level 3

W99RT

Level 4

12EXP

Level 5

JUL98 or CAT93

Level 6

Z9A8L

Level 7

3VW50 or 11TTY

Level 9

EAGLE

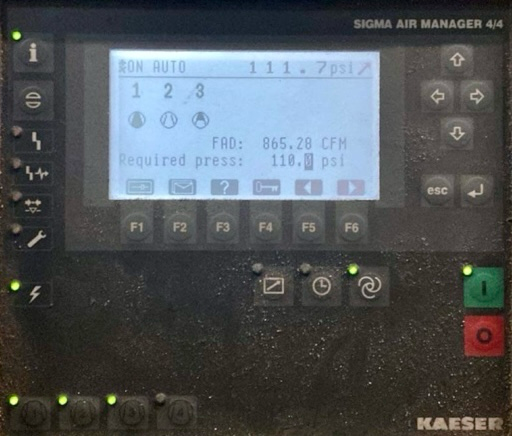

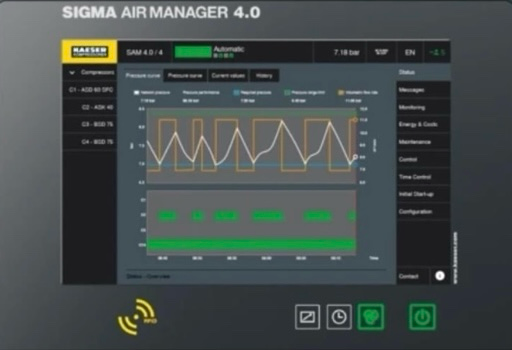

User ManualSigma Air Manager 4.0

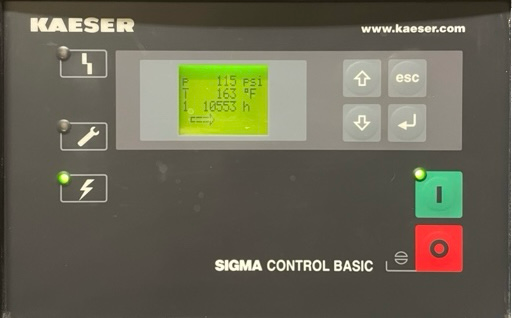

Sigma Basic

Fault 1

Emergency Stop

Fault 2

Motor overload or VFD alarm if equipped.

Fault 3

Back pressure.

Fault 4

Maximum discharge temperature exceeded.

Fault 5

Refrigerated dryer fault.

Fault 6

Analog input fault.

Fault 7

Maximum controller housing temperature exceeded.

Fault S

Maintenance due.

Fault T

Back pressure, check rotation.

Fault i

Machine below minimum starting temperature.

Fault p

Pressure relief valve check mode enabled.

Parameter Adjustment

CERES

Service

BASIC

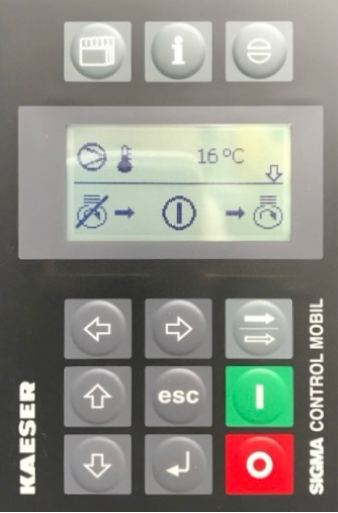

Tech HandbookSigma Control Mobil

1100

Engine oil pressure.

1101

Engine oil pressure sensor fault.

1110

Engine coolant temperature high.

1111

Engine coolant level low.

1112

Engine coolant temperature sensor defective.

1120

Engine turbo air pressure is too high or low.

1121

Engine turbo air temperature too high.

1122

Engine turbo air temperature sensor.

1123

Engine turbo air temperature sensor.

1130

Endings fuel level low.

1131

Engine fuel temperature high.

1132

Engine fuel pressure low.

1133

Engine fuel temperature sensor defective.

1134

Engine fuel pressure sensor defective.

1135

Engine fuel pump.

1140

Engine alternator defective.

1141

Battery voltage is too high or low.

1150

Engine electronics.

1151

Engine electronics communication fault, engine side.

1152

Engine electronics communication fault, ECM side.

1160

Engine rail pressure sensor.

1161

Speed sensor.

1170

Starting fault, 3 failed attempts to start.

1200

Compressor over temperature.

1201

Compressor over pressure.

1300

Controller memory fault.

1301

Bus communications with engine electronics.

1302

Bus communications with display unit.

1303

Controller over temperature.

1304

Controller power supply.

1400

Quick stop fault.

1410

Oil separator tank pressure sensor open circuit.

1411

Oil separator tank pressure sensor short circuit.

1412

Inlet valve pressure sensor open circuit.

1413

Inlet valve pressure sensor short circuit.

1414

Compressor temperature sensor open circuit.

1415

Compressor temperature sensor short circuit.

1416

Fuel level sensor open circuit.

1417

Fuel level sensor short circuit.

1420

Vent valve open circuit.

1421

Vent valve short circuit.

1422

Auxiliary vent valve open circuit.

1423

Auxiliary vent valve short circuit.

1424

Inlet valve control valve open circuit.

1425

Inlet valve control valve short circuit.

1426

Frost protection valve open circuit.

1427

Frost protection valve short circuit.

1430

Manual stop in automatic mode.

1450

Controller blocked, GPS/GSM monitoring.

1470

Automatic mode start fault.

2100

Change engine oil and filter.

2101

Change engine air filter.

2200

Change compressor oil and oil filter.

2201

Change compressor air filter.

3100

Engine oil pressure low.

3110

Engine coolant temperature high.

3121

Engine turbo air temperature high.

3130

Engine fuel level low.

3133

Engine fuel filter water level.

3200

Compressor over temperature.

3201

Compressor over pressure.

3400

Battery charging voltage.

Maintenance

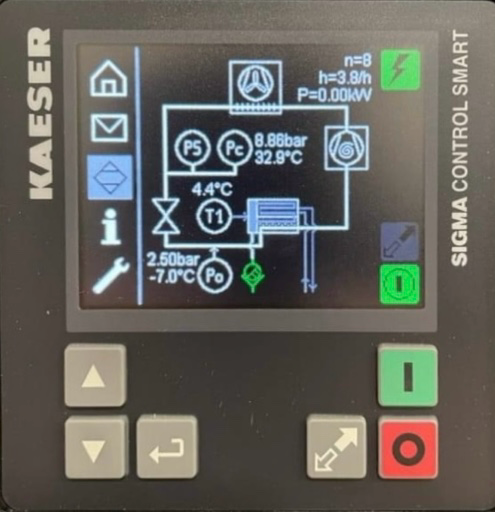

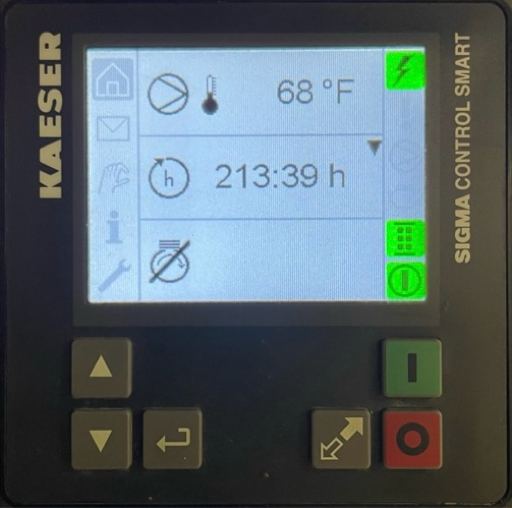

4128Sigma SMART Dryers

101

Safety pressure switch PS.

102

Motor protection switch for refrigerant compressor.

103

Switching frequency for refrigerant compressor is too high.

104

Motor protection switch for refrigerant compressor.

105

Fan motor temperature switch.

106

Pressure sensor P0 for refrigerant pressure open circuit on the low-pressure side.

107

Pressure sensor P0 for refrigerant pressure short circuit on the low-pressure side.

108

Pressure sensor Pc for refrigerant pressure open circuit on the high-pressure side.

109

Pressure sensor Pc for refrigerant pressure short circuit on the high-pressure side.

110

Temperature sensor T1, compressed air temperature, has an open circuit.

111

Temperature sensor T1, compressed air temperature, has a short circuit.

112

Power supply phase sequence incorrect.

113

CAN bus communication fault (display unit).

114

CAN bus communication fault (controller module).

115

Display unit internal temperature too high.

116

Control module internal temperature too high.

117

Low side refrigerant pressure is too low.

201

Switching frequency for refrigerant compressor is too high.

202

Condensate drain fault.

203

High dew point, yellow level.

204

High dew point, red level.

301

Clean condenser maintenance alarm.

302

Condensate drain maintenance alarm.

User ManualSigma SMART Portable Compressors

1100

Drive engine oil pressure low (p76).

1110

Engine coolant temperature high (T70).

1111

Engine coolant level low.

1121

Engine turbo air temperature high (T73).

1124

Engine air flow meter.

1130

Engine fuel level low.

1132

Engine fuel pressure low.

1135

Engine fuel pump.

1136

Engine floor pan fluid level.

1137

Engine fuel solenoid.

1140

Engine generator does not load.

1150

ECU other faults.

1151

ECU -> PLC communication.

1160

Engine sensor rail pressure.

1161

Engine speed sensor.

1162

Engine speed high.

1164

Engine fuel system.

1165

Engine speed low.

1170

Start error auto mode.

1180

Diesel particle filter.

1186

Exhaust treatment temperature high.

1200

Air end discharge temperature high.

1201

Oil separator tank pressure high.

1300

PLC memory fault.

1302

PLC -> HMI modem communication.

1303

PPLC temperature high.

1304

PLC power supply.

1306

PLC -> ECU communication.

1310

Watchdog error.

1311

I/O module error.

1400

Emergency stop.

1410

Oil separator tank sensor wire break.

1412

Inlet valve pressure sensor wire break.

1414

Air end discharge temperature sensor wire break.

1416

Fuel level sensor wire break.

1420

Vent valve wire break.

1424

Inlet valve control valve wire break.

1450

GSM modem controller lock.

2100

Change engine oil filter.

2101

Change engine air filter.

2102

Change engine oil.

2200

Change compressor oil filter.

2201

Change compressor air filter.

2202

Change compressor oil.

3112

Engine coolant temperature sensor (T70) fault.

3120

Engine turbo air pressure error.

3124

Engine air flow meter error.

3130

Engine fuel level low.

3135

Engine fuel pump.

3136

Engine fuel filter water level.

3150

ECU other faults.

3154

Drive engine sensor fault.

3155

Drive engine actuator fault.

3164

Fuel system error.

3165

Engine speed low.

3185

Engine exhaust treatment error.

3188

Engine exhaust treatment, regeneration required.

3200

Air end discharge temperature high.

3201

Oil separator tank pressure high.

3303

PLC temperature high.

3313

HMI temperature high.

Kaeser