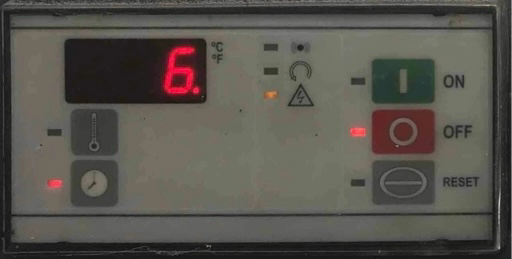

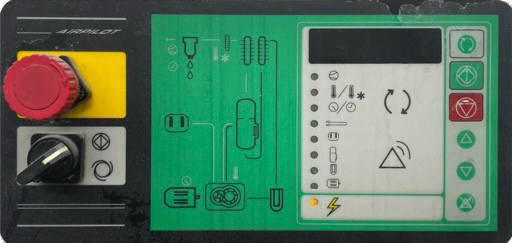

Air Pilot

Service Menu

Hold up and down arrow keys for 5 seconds until all LEDs flash then select code 02.

User GuideAirplus

Alarm A.01

Air Filter Vacuum Switch

Alarm A.02

High Discharge Pressure

Alarm A.03

High Oil Temp

Alarm S.01

Oil Change Due

Alarm S.02

Air Filter Due

Alarm S.03

Oil Filter Due

Alarm S.04

Separator Due

Alarm S.06

General Service Due

Distributor

0009

Error A.03

Motor Overload

Error A.04

Phase Monitor

Error A.05

Emergency Stop

Error A.07

Temp Sensor Fault

Error A.12

High Discharge Pressure

Error A.13

Pressure Transducer Fault

Error A.20

High Pressure Switch

Error A.25

High Temp Switch

Error A.33

Power Loss While Loaded

Error E.04

Power Loss or Low Voltage

Manual Number

13-19-608

Run Inhibit 1.01

Low Oil Temp. See Td.

Technician

0121

User

0100

Reset Guide

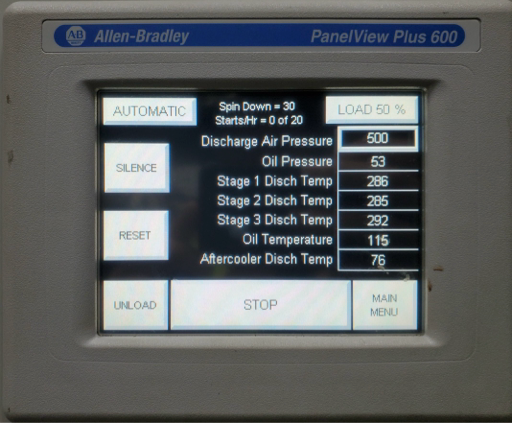

User ManualAirsmart

101

Fan fault, a cooling fan is over temperature.

102

Drive 1 fault, the main motor VFD has shut down.

103

The second stage motor VFD has shut down.

104

The cooler fan motor VFD has shut down.

105

Emergency stop, the emergency stop button has been pressed.

106

Open pressure transducer PT5 shutdown.

107

High plant pressure shutdown, the plant pressure is greater than 190 psi (13 bar).

108

Shorted pressure transducer PT5 shutdown.

109

Open pressure transducer PT4 shutdown.

110

High separator pressure shutdown, separator pressure is greater than 190 psi (13 bar).

111

Shorted pressure transducer PT4 shutdown.

112

Open pressure transducer PT3 shutdown.

113

High reservoir pressure shutdown, the oil reservoir pressure is greater than 190 psi (13 bar).

114

Shorted pressure transducer PT3 shutdown.

115

Open pressure transducer PT2 shutdown.

116

High interstage pressure shutdown, interstage pressure is greater than 190 psi (13 bar).

117

Shorted pressure transducer PT2 shutdown.

118

Open pressure transducer PT1 shutdown.

120

Shorted pressure transducer PT1 shutdown.

121

Open thermistor T5 shutdown.

122

High package discharge temperature shutdown, the package discharge temperature is greater than 158°F (70°C).

123

Shorted thermistor T5 shutdown.

124

Open thermistor T4 shutdown.

125

High separator temperature shutdown, the separator temperature is greater than 240°F (116°C).

126

Shorted thermistor T4 shutdown.

127

Open thermistor T3 shutdown.

128

High discharge temperature shutdown, the air end discharge temperature is greater than 240°F (116°C).

129

Shorted thermistor T3 shutdown.

130

Open thermistor T2 shutdown.

131

High interstage temperature shutdown, the interstage temperature is greater than 240°F (116°C).

132

Shorted thermistor T2 shutdown.

133

Open thermistor T1 shutdown.

134

High inlet temperature shutdown, the inlet air temperature is greater than 113°F (45°C).

135

Shorted thermistor T1 shutdown.

136

High separator rate shutdown, rapid temperature rise at the separator.

137

High discharge rate shutdown, rapid temperature rise at the air end.

138

Fan starter shutdown, the fan starter auxiliary contact does not match the expected state.

139

Drive 1 start, main motor VFD failed to start.

140

Drive 2 start, second stage motor VFD failed to start.

141

Drive 3 start, cooling fan motor VFD failed to start.

142

Power failure, there was a loss of power to the unit.

143

XB1 communication error, internal communication error, replace controller.

144

Drive 1 communication error, there was a communication error between the controller and the main motor VFD.

145

Drive 2 communication error, there was a communication error between the controller and the second stage motor VFD.

146

Drive 3 communication error, there was a communication error between the controller and the cooling fan motor VFD.

147

Optional shutdown, a digital input programmed for optional shutdown has been triggered.

148

Low voltage shutdown, the digital input programmed for low voltage shutdown has been triggered.

149

Phase sequence shutdown, the digital input programmed for phase sequence shutdown has been triggered.

150

Motor over temperature shutdown, the digital input programmed for motor over temperature shutdown has been triggered.

151

Water pressure shutdown, the digital input programmed for water pressure has been triggered.

152

High vibration shutdown, the digital input programmed for high vibration has been triggered.

153

Zero transducer PT5 shutdown, transducer PT5 not properly zeroed or a vacuum is present.

154

Zero transducer PT4 shutdown, transducer PT4 not properly zeroed or a vacuum is present.

155

Zero transducer PT3 shutdown, transducer PT3 not properly zeroed or a vacuum is present.

156

Zero transducer PT2 shutdown, transducer PT2 not properly zeroed or a vacuum is present.

157

Zero transducer PT1 shutdown, transducer PT1 not properly zeroed or a vacuum is present.

160

Controller internal error, the controller has failed and needs to be replaced.

161

EEPROM restored, main parameter set in controller memory.

164

Invalid model table shutdown, an invalid model was selected during factory setup or during a controller replacement.

165

Low DC voltage shutdown, the power to the controller is less than 18.5VDC +/- 1.5VDC.

166

High dryer temperature shutdown, the temperature at the dryer is greater than 120°F (49°C).

167

Open thermistor T6 shutdown.

168

Shorted thermistor T6 shutdown.

169

CM table invalid shutdown, model table in memory is corrupted.

170

Actuator communication error shutdown, an error occurred with communications between the controller and precision mixing valve.

171

Low oil pressure shutdown, the oil pressure has dropped below (interstage pressure + 2.5 psi).

172

Sequencer communication error shutdown, communications between the controller and communications module has failed.

173

Open pressure transducer PT6 shutdown.

174

Shorted pressure transducer PT6 shutdown.

175

Zero transducer PT6 shutdown, transducer PT6 not properly zeroed or a vacuum is present.

176

Open pressure transducer PT7 shutdown.

177

Shorted pressure transducer PT7 shutdown.

178

Zero transducer PT7 shutdown, transducer PT7 not properly zeroed or a vacuum is present.

179

Main motor starter shutdown, the main motor starter auxiliary contact does not match the expected state.

201

Low sump pressure shutdown, pressure in the oil reservoir has been less than 15 psi (1 bar) for more than 1 minute.

202

Change separator shutdown, separator differential pressure is greater than 15 psi (1 bar).

301

Change separator, separator differential pressure greater than 8 psi.

302

Change air filter, air filter vacuum switch tripped.

303

Change air filter, air filter maintenance timer has elapsed.

304

Change oil filter, oil filter maintenance timer has elapsed.

305

Change oil, oil maintenance timer has elapsed.

306

Low ambient temperature, package discharge temperature below 40°F (4°C).

307

Low ambient temperature, package separator temperature below 40°F (4°C).

308

High separator temperature, separator temperature greater than 225°F (107°C).

309

High plant temperature, the package discharge temperature is greater than 149°F (65°C).

310

High inlet temperature, the package inlet temperature is greater than 113°F (45°C) or on some models, 104°F (40°C).

315

Change separator, the separator maintenance timer has elapsed.

316

High discharge temperature, temperature at the air end is greater than 225°F (107°C).

317

High interstage temperature, temperature at the interstage is greater than 225°F (107°C).

318

Optional alarm, a digital input programmed for optional alarm has been triggered.

320

Change oil filter, oil filter differential switch was triggered.

321

Low voltage alarm, the digital input programmed for low voltage alarm has been triggered.

322

Motor over temperature, the digital input programmed for motor over temperature has been triggered.

323

Water pressure alarm, the digital input programmed for water pressure has been triggered.

324

High vibration, the digital input programmed for high vibration has been triggered.

325

Low discharge temperature, the discharge temperature of the air end is less than 185°F (85°C). Applicable to two-stage units only.

326

High dryer temperature, the temperature at the dryer is greater than 100°F (38°C).

327

Motor lubrication alarm, the motor lubrication maintenance timer has elapsed.

328

Low plant pressure, the compressor is unable to maintain the set target pressure.

329

Low oil pressure, the oil is less than (interstage pressure + 5 psi). Applicable to two-stage units only.

330

Main motor VFD heat sink temperature is greater than 175°F (79°C).

331

Second stage motor VFD heat sink temperature is greater than 175°F (79°C).

332

Change control panel filter, the control panel filter maintenance timer has elapsed.

333

Dryer alarm, the integrated air dryer has shut down.

334

Oil sample due, the oil sample maintenance timer has elapsed.

Config Adjust

407

Manual I/O

9091

Manual Number

13-17-600 for compressors, IQ-7-200 for blowers. 13-17-604 for sequencing and communications.

Prog I/O Adjust

8412

Comm Module Manual

Quick Reference

User Manual

User Manual (Blowers)Connect 12

Service

7555

Setup Wizard

7777

Snapshot

7123

Technician

7070

Modbus Manual

Profibus Manual

User ManualDigipilot

Diagnostics

Up Down - + Up Down

Machine Config

- + Up Down - +

Regulation

+ - Down Up + -

Service

Up Down - + Up Down

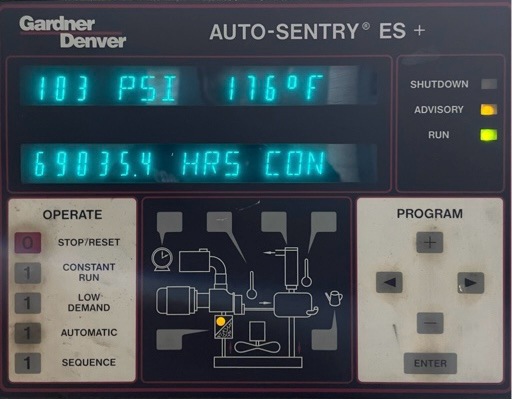

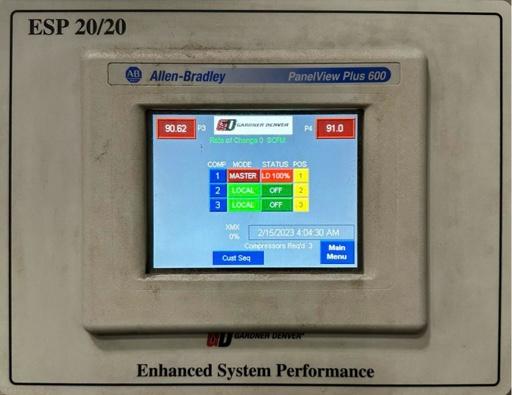

User ManualESP Series 1000

Engineer

120741

Factory

060644

Operator

091101ESP Series 7800 (Early)

Level 1

120741

Level 2

060644

Level 3

0201ESP Series 7800 (Late)

Engineer

120741

Factory

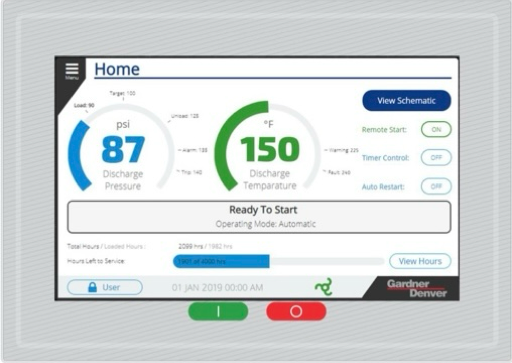

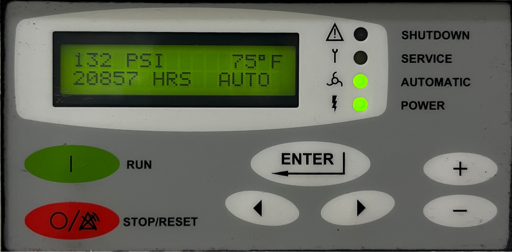

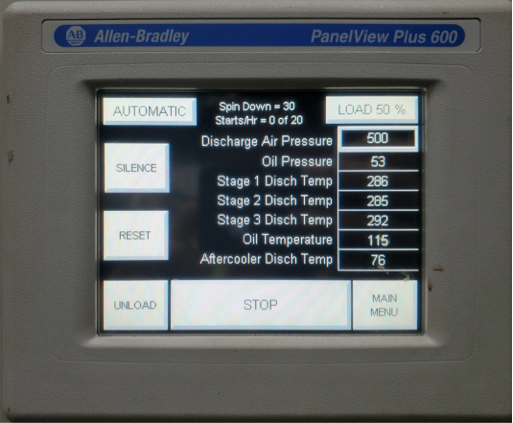

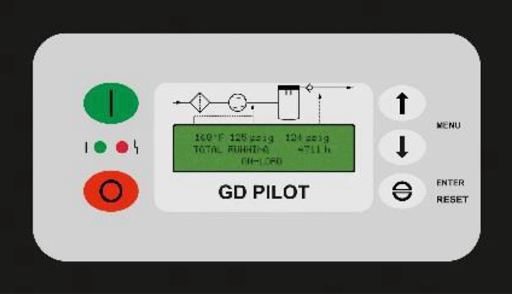

060644GD Pilot

Change Units

Press and hold Enter/Reset then scroll with down arrow.

Infinite Auto Restart

8879

Rotation Off

9989

Rotation On

9988

Setup

2213

Specialist

0102

Speed Lock

9466

Technician

3002

User

3022

Quick Reference

Setup Code Guide

User Manual Fixed Speed

User Manual Variable SpeedGD Pilot SE

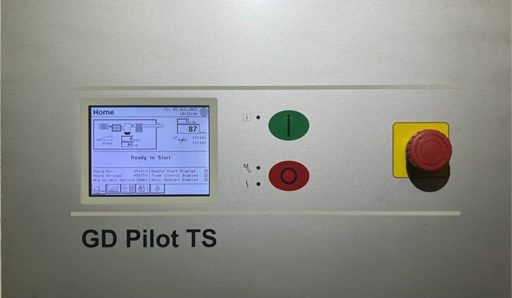

GD Pilot TS

BLS Enable

1234

Infinite Auto Restart

8879

Maintenance

3100

Setup

02213 Code defaults controller.

Snapshot

7123

Specialist

0102

Speed Lock

09466

Technician

03002

User

3022

Quick Reference

User ManualGD Pilot XTS

Alarm Logging

50

BLS Enable

1234

Infinite Auto Restart

8879

Maintenance

3100

Setup

02213 Code defaults controller.

Snapshot

7123

Specialist

0102

Speed Lock

09466

Technician

03002

User

3022

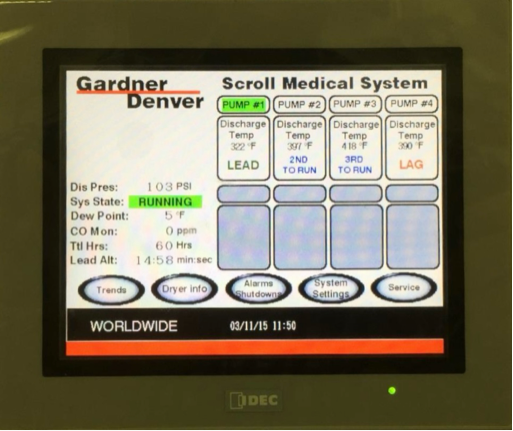

User ManualQ Pilot

Customer

0120

Service

2460S Controller

Manual Number

13-8-609, section 4.

Pressure Error E01

Failure of Discharge Pressure Transducer.

Pressure Error E02

Failure of Sump Pressure Transducer.

Pressure Error E03

Failure of both Pressure Transducers.

Pressure Error E04

Emergency Stop.

Temperature Error E01

Failure of Discharge Temperature Sensor.

Temperature Error E02

Failure of Separator Temperature Sensor.

Temperature Error E03

Failure of Both Temperature Sensors.

User Manual

Gardner Denver